Senior Research Investigator Lucy Hawarden monitored production at a manufacturing facility in Asia while working from home in the U.K.

In normal times, Lucy would have boarded an international flight to the facility, a contract manufacturing partner supporting the medicine’s development. A key milestone was at hand involving the production of the drug’s pediatric formulation. As “lead formulator” in charge of that dosage form she would have been there to monitor the activities in person. While being on-site wasn’t possible due to COVID-19 travel restrictions, the technology still allowed her to be present.

“I was able to remotely view all stages of the clinical manufacture, covering dispensing and blending, granulation, compression and coating, and also give feedback to the team there,” she said. “The batches were successfully manufactured and released, keeping timelines for the drug’s development on track.”

Augmented reality in healthcare: biopharmaceutical manufacturing

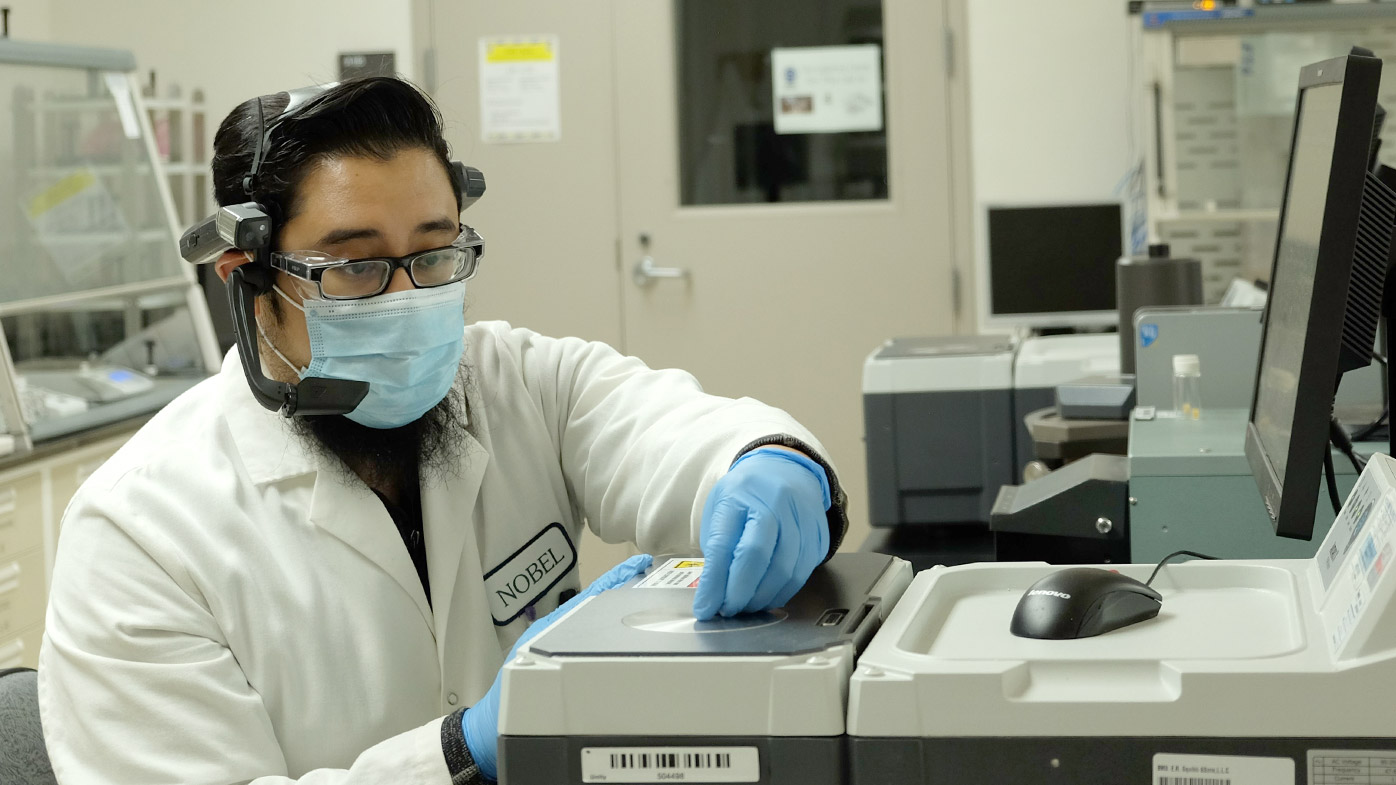

COVID-19 has prompted rapid adoption of video and web conferencing tools across many workplaces, including Bristol Myers Squibb. This technology goes a step further at the company’s Global Product Development & Supply (GPS) organization, a business unit that oversees worldwide product development, manufacturing and delivery of the company’s medicines. Here the new tools include specialized headsets that work like hands-free, wearable tablets and connect users with real-time video and data from across the company’s global network of sites.

It’s all part of the ARGILE program, or Assistive Reality Gadgets in Lab Environments. Program Lead Nobel Vale, a principal scientist in the GPS Product Development group, launched the initiative in 2018 to explore the feasibility and versatility of assistive reality tools to help accomplish certain work remotely.